From Lab To Market: How GMP Manufacturing Accelerates Biotech Innovations

Biotechnology is not new, but the demand for its applications in the modern world makes it an intensely competitive field. Manufacturers in various sectors want to get the best innovative technologies in progress as quickly as possible in order to reach the market first. Hence, there is a lot of pressure to speed up the process as much as possible.

According to a recent Grand View Research, Inc. report, the worldwide biotechnology industry is projected to grow to a staggering USD 2.44 trillion by 2028. Key factors fueling this growth are the urgent needs for innovative products, strong financial backing, supportive government regulations, and an escalating requirement for synthetic biology.

However, a crucial step bridges the gap between a ground-breaking discovery and real-world application: passing the stringent standards and requirements of Good Manufacturing Practice (GMP). Noncompliance can cause production and delivery delays- and at its worst, failure to launch the product. The consequences are not limited to loss of income, with major repercussions including canceled contracts, loss of reputation, and product bans or recalls.

Fortunately, there are ways to accelerate the process from lab to market in in a GMP manufacturing facility. This article provides tips on how this can be done.

Accelerating Biotech Innovations

The three principal biotechnology sectors – medicine, industry, and agriculture – are experiencing remarkable growth, driven by strong competition and the demand for their products. Here are the ways that GMP Manufacturing can cut the lab-to-market timeline:

Streamlining Regulatory Approval

For biotech innovations to transition into marketable products, they must receive the nod of regulatory bodies like the FDA. The process can be arduous and time-consuming, often taking years to complete. However, by trusting the GMP process, regulatory agencies often fast-track approval of products, such as vaccines; shaving the approval process down by months or even years. By gaining regulatory approval, these firms are on their way to market confidence, and commercial success.

Building Market Confidence: Reputation And Trust

GMP manufacturing is not merely a regulatory hurdle but also a trust-building exercise with potential consumers. This is because the public is understandably cautious about biotech products’ health and safety implications.

Producing high-quality, safe, and effective products builds a reputation for reliability. This can lead to stronger partnerships, more collaboration, faster innovation – and loyalty for the brand and its subsequent products.

Mitigating Risk

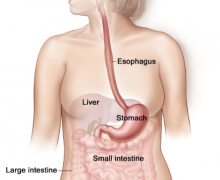

Biotech is inherently risky, with the potential for significant losses if a product fails in late-stage trials or post-market due to quality or safety issues. GMP manufacturing minimizes such risks, enabling companies to identify and rectify any problems during production. This proactive approach to risk management can prevent costly recalls and protect consumers as well as the company’s reputation.

For instance, by ensuring consistent quality and safety during the development of a novel drug, GMP can reduce the risk of failure in later stages, such as during clinical trials. This can save time and resources, allowing faster development and commercialization of innovative products.

Enabling Scalability

Scalability is a key challenge in biotech. Transforming a laboratory process into large-scale manufacturing can be complicated. GMP provides a framework for scaling up production, thereby ensuring the process’s repeatability and reliability.

By following GMP, companies can commercialize production, speeding up its market entry while maintaining quality and consistency.

Process Optimization And Continuous Improvement

GMP manufacturing practices emphasize process optimization to ensure efficient and cost-effective production. Implementing GMP principles helps identify and eliminate inefficiencies in the manufacturing process, leading to improved productivity, reduced waste, better products, and faster time to market.

Increase Investor Confidence

GMP compliance can increase investor confidence in a biotech company. This can lead to more funding, which can be used to accelerate research and development.

GMP Digitalization

Moreover, the trend towards digitalization and AI could revolutionize GMP manufacturing. By leveraging machine learning algorithms, companies could enhance the efficiency and precision of quality control processes, predicting and preventing defects before they occur.

As biotech continues to evolve, so will GMP manufacturing. The advent of personalized medicine, for example, poses new challenges for large-scale production. To meet these demands, GMP guidelines must be adaptable, evolving to match the pace of innovation while maintaining their core commitment to quality and safety.

Takeaways

GMP manufacturing is an essential element of biotech development and a catalyst for innovation. It fast-tracks regulatory approval, instils market confidence, mitigates risks, and enables scalability – all of which are crucial to the successful commercialization of biotech products. As the sector pushes scientific discovery boundaries, GMP manufacturing will remain central to translating these breakthroughs into real-world solutions.