How Is Hemp Extract Obtained: From Production to Processing

More than 33% of adult Americans have used CDB in some form, and interest in CBD products is rising. Statistics indicate that the industry will likely boom and grow to a 7.8 billion industry in 2022 with an unbelievable range of products. The problem with the hemp source of CBD is that it is closely related to the marijuana plant that contains high levels of the psychoactive compound THC.

Since the U.S. Drug Enforcement Administration (DEA) has categorized products containing more than 0.3% of delta-9 tetrahydrocannabinol (THC) as a Schedule I substance, it has become critical to make the clear distinction between hemp and marijuana, and the products extracted from them.

From Production to Processing – Hemp Plants Are Beneficial for the Planet

Both hemp and marijuana belong to the same species of cannabis plants. The key difference is that the hemp plant is specifically cultivated to contain less than 0.3% THC. Hemp can be grown in dense clusters enabling the concentrated use of land resources, and a single crop is ready for harvesting within 60 days. Further, crop rotation diverts the plant nutrients back into the ground, breaking down and enriching the soil for the next crop. Not only does the plant produce large quantities of biomass after processing, but several by-products can be used to make textiles, fibers, rope, and various other items. The end CBD makes consumer products like a topical pain reliever, cosmetics, sleep aids infused with melatonin, and skincare ranges.

Hemp Processing Techniques Are Designed to Remove Schedule I THC

Hemp plants are grown on farms where the soil is carefully tested for herbicides and pesticides, and farming is done under the supervision of the state department of agriculture. After harvesting, the plants are laid out in a ventilated area where they air dry naturally over 3 to 4 weeks. Then, the plants are diverted toward extraction facilities where the CBD content is carefully separated with an intricate, multi-step procedure.

Step 1 – CO2 Extraction

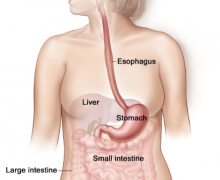

CO2 extraction is the first step where the entire plant containing proteins, fats, waxy materials, and cell walls, is processed. Supercritical CO2 is the state where the compound is suspended between the liquid and gaseous state. When infused with this CO2, the hemp plant releases its wax and oil content to create a substance that has the consistency of crude oil. At this stage, it resembles a thick gooey mass containing CBD at 50% to 60%. About 90% of the residue is diverted to disposal, recycling, or reuse processes after extraction. Since the extract is a concentrated version, it contains high levels of THC, which is later separated from the end product.

Step 2 – Purification by Winterization

The winterization process is intended to purify the CBD concentrate further by removing the waxes, fats, and lipids content. After treating with alcohol, the product is cooled rapidly so that the waxes sweat out and can be removed from the substance.

Step 3 – Extracting the Full-Spectrum Oil (FSO)

The next step involves removing the alcohol content using an evaporation method. The substance now becomes a full-spectrum oil (FSO) with a 60%-70% CBD content. At this stage, the substance contains 2% to 3% of THC and is an intermediary hemp material that is unfit for consumer use. The actual percentages of THC can vary according to the content in the original hemp plant.

Step 4 – Short-Path Distillation System

The FSO is then run through a short-path distillation system to refine it thoroughly and remove all the residual impurities. Only minimal traces of the aromatic terpenes compounds now remain in the FSO, which contains 75% to 80% CBD.

Step 5 – THC Remediation and Crystallization Process

The FSO now undergoes the THC remediation step to remove the final traces of THC using chemical processes or chromatography. The final purification is done using another solvent to extract CBD in crystal form is concentrations of 99.5%. This is the final CBD isolate in the form of a white powder used to make consumer products.

So you see, the processing and extraction systems are designed to remove all traces of THC from CBD products, making them safe of use without any risk of psychoactive effects.