7 Types Of Liquid Measuring And Dosing Equipment

Pumping equipment is used daily for domestic and industrial purposes. Liquid transfer pumps supply fluids like water, beverages, manufacturing chemicals, and even laboratory reagents from one point to another.

However, there are numerous instances where you need to deliver only the exact quantity of liquid required. For instance, research and medical laboratories, manufacturing plants, and commercial beverage dispensers need accurate liquid measuring equipment.

A liquid dosing pump is a device designed to transport a precise quantity of liquid media within a given time frame. Liquid measuring pumps draw liquid into a chamber or container until it’s full, after which it’s dispensed in precise doses at a predetermined rate. For example, an exact amount of chlorine is added to domestic water reservoirs after a specified period to guarantee its safety.

Liquid measuring pumps are used extensively in hospitals and laboratories to administer medicine and liquid matter intravenously. In the food and beverage processing industry, liquid dosing equipment is widely used to measure the right proportions of various ingredients.

These pumps are designed differently depending on the liquid media to be pumped and the required pressure. Here’s a general overview of its various types:

Types Of Liquid Measuring Equipment

Diaphragm Pumps

A diaphragm measuring pump is a positive displacement pump that uses a diaphragm to draw and expel liquids into and from a container. The movement of the diaphragm creates a vacuum that pulls fluids into a chamber through an inlet valve. Once it’s full, the diaphragm retracts, emptying the liquid through an outlet valve.

Diaphragm pumps are easy to calibrate and, as a result, offer great precision in liquid dosing, placing them in the category of critical biosafety laboratory equipment.

There are two common types of diaphragm pumps:

Constant injection diaphragm pumps: Their inlet and outlet points are equipped with a diaphragm, piston, and valve. These pumps are ideal when it’s critical to determine and set the flow rate of liquids to be transferred.

Constant injection pumps allow different chemicals, including medicines, to be dosed at various rates. Diaphragm injection pumps are ideal for hospitals and medical laboratories, given their high accuracy levels.

Pulse injection pumps: They release liquids in pulses, so the duration between pulses determines the flow rate. Although they have simpler designs and are cheaper than constant injection pumps, they don’t offer the same level of precision. Therefore, they’re unsuitable where high-accuracy dosing is required.

Peristaltic Pumps

These valve-free pumps transfer a wide range of chemicals used during water treatment, plastic production, food manufacturing, and paper production, among others. Peristaltic pumps are corrosion-resistant, making them ideal for transferring abrasive, acidic, and sensitive fluid matter. They’re highly accurate, providing precise dosing in factories where they’re primarily used in industrial liquid transfers.

Solenoid Pumps

This liquid measuring pump uses electromagnetic power as its driving force. Solenoid metering pumps have a simplistic design because of their few moving parts. They can be programmed to discharge a predetermined amount of liquid, and because they have a higher discharge volume, they are ideal for use with most liquid chemicals.

Piston Metering Pumps

These positive displacement pumps can move precise amounts of fluid at a constant rate and in stages. Piston measuring pumps are ideal for laboratory dispensing, chemical processing, and water treatment. They also offer an economical method of transferring fluids.

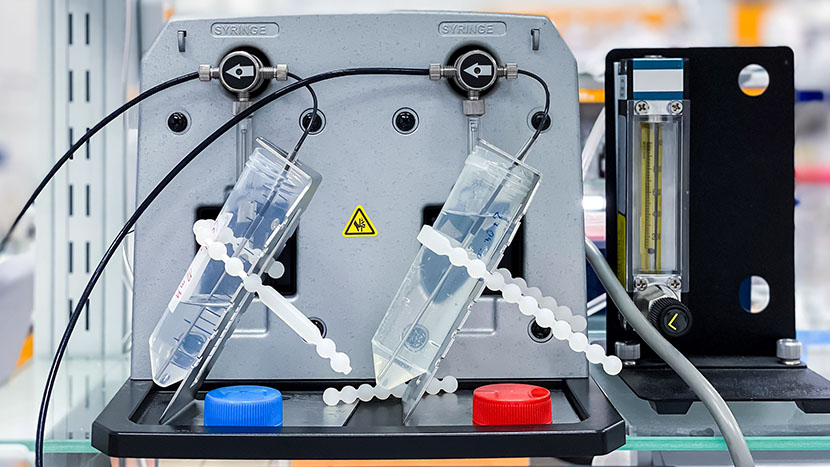

Syringe Metering Pumps

Also known as infusion syringe metering pumps, they use pistons to draw and discharge fluids. They have specified speed and flow rates and are used mainly in hospitals to dose and administer medication. They are the preferred option for biologists because they’re made to work with a variety of syringes.

Chemical Metering Pumps

These pumps are mainly used for adding chemicals to an ongoing industrial process, with consistent flow rate being their most notable feature. They are highly accurate and are primarily used in mining operations to extract precious metals from ore.

Gear Pumps

These pumps are highly versatile and are ideal for measuring a wide range of liquid media, including adhesives, lubricants, and sealants. They’re considered some of the most efficient liquid measuring pumps, making them suitable for general engineering and other sectors like aviation and automotive.

Final Word

There are numerous industrial application requirements for precise and accurate dosing of liquid media. While peristaltic pumps may be ideal in manufacturing, diaphragm measuring pumps are best suited for various laboratory applications. In order to ensure the ideal liquid dosing pump, it’s important to purchase from a reputable supplier. It also helps to understand your unique liquid transfer needs to determine the best one to use.